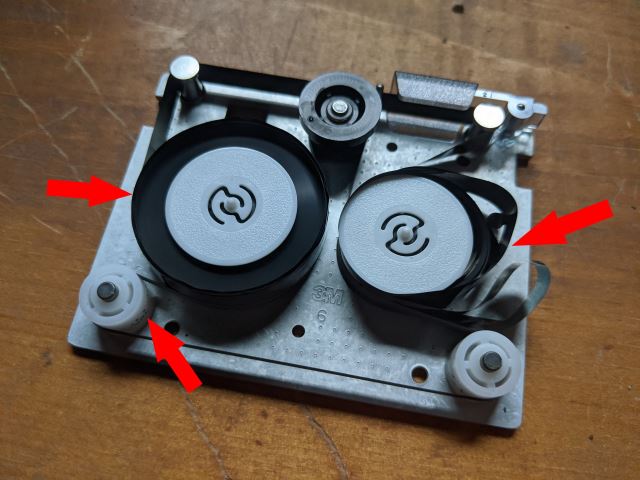

In another of my recent data recovery cases, the patient was a QIC-80 (DC 2000 mini cartridge) tape that was in pretty bad shape. From the outside I could already see that it would need physical repairs, so I opened it up and found a harrowing sight:

The problem with QIC cartridges in general is that they use a tension band to drive the tape spools. If you look at a QIC cartridge, it’s completely enclosed, except for a plastic wheel that sticks out and makes contact with the capstan mechanism when it’s inserted into the tape drive. The flexible tension band is tightened in such a way that it hugs the tape spools and drives them using physical friction.

This tension band is a major point of weakness for these types of tapes, because the lifespan of the band is very much finite. When the tape sits unused for many years, the band can stiffen or lose its friction against the tape spools, which can result in one of two scenarios:

The tension band can break, which would make the cartridge unusable and would require opening the cartridge and replacing the band. This is actually not the worst possible outcome because replacing the band, if done properly, isn’t too disruptive of the tape medium itself, and usually doesn’t result in any data loss.

A much worse scenario is if the tension band becomes weakened over time, such that it no longer grips the spools properly, so that the next time you attempt to read the cartridge, it will spin the spools inconsistently (or cause one of the spools to stall entirely), which will cause the tape to bunch up between the spools, or bend and crease, creating a sort of “tape salad” inside the cartridge, all of which can be catastrophic for the data on the tape. In this kind of case, the cartridge would need to be disassembled and the tape manually rewound onto the spools, being extremely careful to undo any folds or creases (and of course replace the band with a new one, perhaps from a donor tape). This will almost certainly result in loss of data, but depends greatly on the degree to which the tape was unwound and deformed.

Note that the tape drive that is reading the tape is relatively “dumb” with respect to the physical state of the tape. It has no way of knowing if the tension band is broken, or if the tape isn’t wound or tensioned properly, or if what it’s doing is damaging the tape even further. Great care must be taken to examine the integrity of the tape before attempting to read it.

With this cartridge, it’s clear that the tension band has failed (but didn’t break). The tape has obviously bunched up very badly on both spools. Less obviously, the white plastic wheels at the bottom show evidence that the tension band has degraded, with bits of residue from the black band being stuck on the wheels. The fix for this cartridge was to remove the bad tension band, clean the white plastic wheels, respool and tighten the tape, and install a new band from a donor tape. After the procedure was complete, more than 99% of the data was recovered. The tape header was readable, as were the volume tables. Only a few KB of the file contents were lost.

Therefore, when recovering data from very old QIC tapes, it’s probably a good idea to replace the tension band preemptively with a known-good band, to minimize the chance of breakage and damage to the tape. This is why I keep a small stockpile of new(er) tapes from which I can harvest the tension band when needed. At the very least, it’s a good idea to open up the cartridge and examine the band before making any attempts to read data from it.